Progressive & Compound Stamping

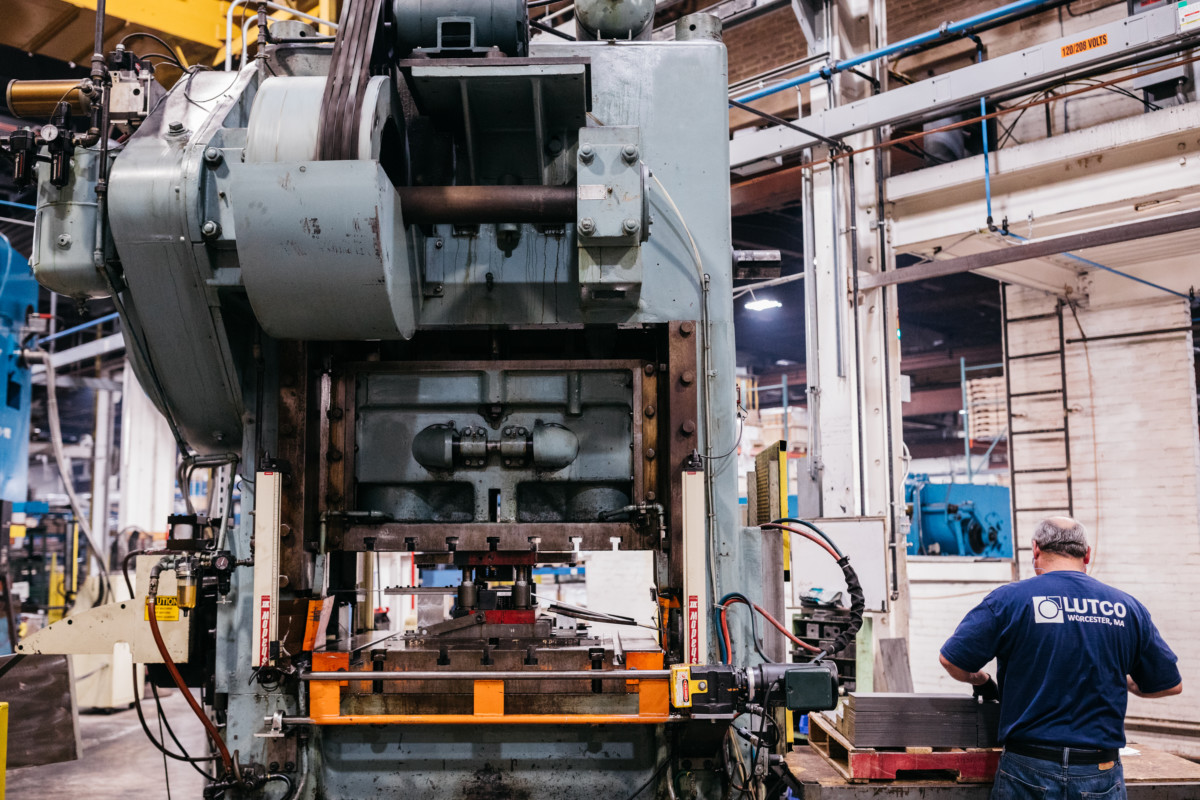

Progressive tooling is the heart of the stamping process at Lutco. Lutco fabricates stampings made off blanking and progressive dies. Press capacity ranges from 40-800 tons and material gauges range from .010″-.375″. Lutco specializes in the contract manufacturing of heavy gauge metal stampings. We are one of the few companies in the northeast with the capabilities to handle thick metal stamping with precision and competitive prices.

Lutco has expertise in subassemblies and can bend, weld, stake, crimp, fasten and press parts together using tools and fixtures while maintaining perfect quality. An extensive secondary department is dedicated to processing additional operations. This allows us to complete part features that could not be incorporated into the primary progressive tooling. Assembly processes may include welding, fastener insertion, staking, semi and fully automated mechanical assembly, and finishing processes.

Lutco can also produce machined stampings which utilize our precision CNC machining to add critical features to complicated stampings. Our state-of-the art equipment includes several Hurco vertical machining centers. By stamping and forming prior to machining any features, we can produce stamping designs for our customers that are more cost-effective and add greater value. We produce smooth edged windows, slots, and holes in parts where a smooth edge condition and tight tolerances are critical. We can work with existing designs or work with clients to develop the best total solution for their application. Contact us today to find out why leading OEMs rely on Lutco.

Contact us to find out why leading OEMs rely on Lutco!