Manufacturing Capabilities

Lutco products are known for their quality because of our excellence in engineering and high-quality workmanship in a suite of precision manufacturing processes, giving you a one-stop solution for many types of components.

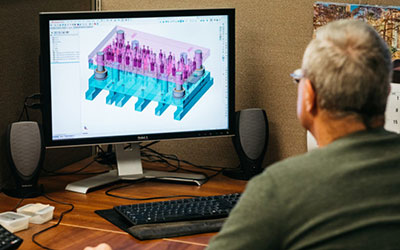

Design Engineering

Lutco offers design assistance to help our customers launch their new products into the market.

Tooling & Fabrication

Tool engineers and technicians enable full in-house production of the necessary tools, fixtures and gauges.

Progressive & Compound Stamping

Progressive tooling is the heart of the stamping process at Lutco. Press capacity ranges from 40-400 tons and material gauges range from .010″-.375″.

Metal Forming

Lutco has the newest press brake technology on the market with broad bending capabilities and a wide range of flexibility.

Welding & Secondary Operations

High speed robotic welders construct reliable welds, built on fixtures and tooling made by Lutco. Capabilities also include resistance spot welding and projection welding.

Component Assembly

Assembly areas are designed for uninterrupted and efficient workflow. Each flexible assembly area is designed for quick changeovers.

Contact us to find out why leading OEMs rely on Lutco!