Bearings come in a wide variety of sizes and designs, each tailored to meet different requirements and priorities. There seem to be nearly as many types of bearings as there are applications putting them to use, but one factor to consider comes down to a simple binary decision: precision or unground? While many engineers and designers will instinctively spec precision bearings, there are many cases where unground bearings will match or even outperform their precision counterparts, depending on the operating environment and specific stresses that will be applied to the bearing. Unground bearings can provide much of the same robust, reliable performance at a lower cost, but should be sourced from a trustworthy, US-based manufacturer to ensure high-quality materials and manufacturing processes.

Precision Bearings vs Unground Bearings

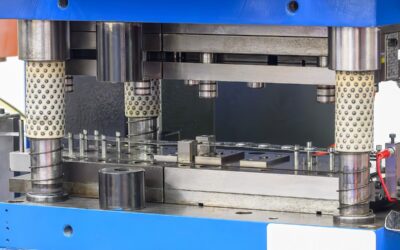

Lutco produces a full line of unground radial and thrust bearing assemblies.

The bearing’s ABEC rating describes the level of manufacturing tolerances. The higher the rating the higher the precision. Ball bearings made with precision levels less than ABEC-1 are considered unground bearings. If a design uses ABEC-1 level bearings or higher there is a good chance there may be a more economical bearing solution for the application.

Unground bearings include a broad range of styles and bearing types, used in an array of applications from lawn and garden wheels, trailer jacks, hoists, trolley wheels and agricultural equipment to name a few.

Standard size bearings are often customized to include many features that can satisfy the demands of a variety of applications. They are available with special bore configurations, extended inner races, flanged housings, and various platings and greases. Standards can also be supplied with a variety of seal types or shields, or open to deliver the most cost-effective solution for the application.

What Are The Main Differences Between Precision Bearings and Unground Bearings?

Two of the most notable differences between precision and unground bearings are the material composition and manufacturing tolerances observed.

Unground Bearing Materials:

Low-carbon steels are typically used in the design of unground bearings as opposed to high carbon through-hardened steels used in precision bearings. Unground bearing raceways are carburized and hardened to develop load carrying capacity and enough wear resistance for good performance under normal operating conditions. Certain applications require unground bearings to be assembled with chrome balls for higher load carrying capacity or stainless balls for corrosion resistance. Exposed surfaces are often zinc plated for corrosion protection or plated with black oxide for aesthetics.

Unground Bearing Tolerances:

Tolerances of unground bearings are typically 10 times greater than tolerances of a precision-ground bearing. For example, where .0005” might be specified for a ground inner race OD of a precision bearing, .005” is the norm for an unground bearing.

Predicting the Life Expectancy of Unground Bearings

Under normal operating conditions the failure mode in unground bearings is typically due to wear of the bearing raceways as compared with metal fatigue or “spalling” in precision bearings. Therefore unground bearings do not follow the uniform statistical life test guidelines set forth by the American Bearing Manufacturers Association (ABMA) common to precision bearings. In precision bearings, calculating when 10% of a population of identical bearings would suffer a fatigue failure under a given load and speed. Rather than developing an industry-standard life calculation similar to what’s used for precision bearings, unground bearing capacities are generally drawn from experience or empirical data, thus life values are typically not stated and any life values that are provided must be regarded as estimates.

Lutco’s Bearing Experts Are Here To Help

An unground bearing can be a cost-effective alternative in low-speed or low-load applications, especially when the bearing is customized for a specific application. Let Lutco show you how to take advantage of the savings and special features we can apply to our designs. Start your search with the Lutco line of standard inch-dimension, radial, thrust, and angular contact ball bearings. Even when one of our standard bearings isn’t the answer, our engineers can develop an economical, modified standard design or “special” for your specific application. Contact the experts at Lutco and put our experience and knowledge to work.